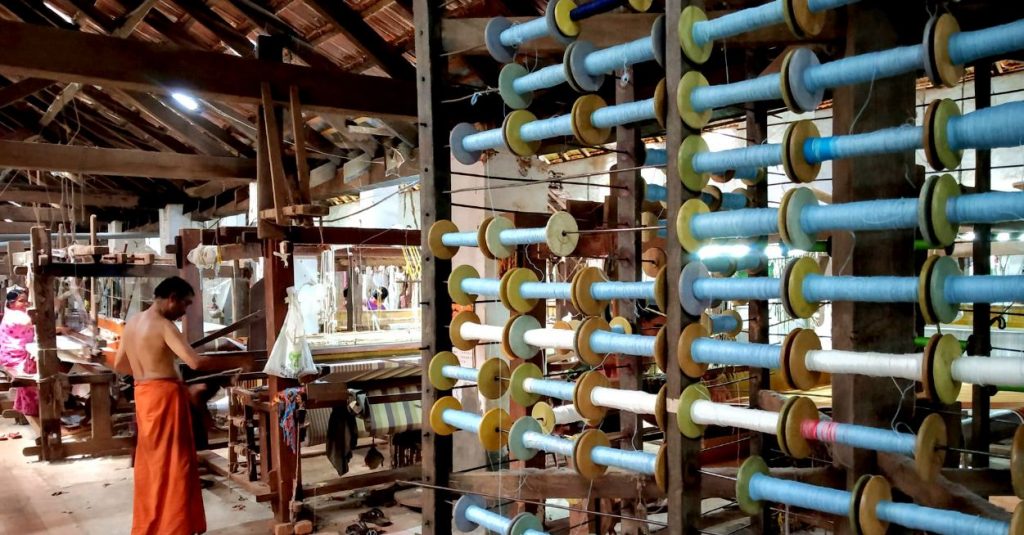

There is something brutally absurd about a handloom weaver — someone who turns patience into fabric — sitting idle because the most basic raw material is missing. Kerala’s handloom sector is not struggling due to lack of skill, lack of demand, or lack of tradition. It is struggling because the loom is staring at an empty spool.

Across the state, cooperative societies report the same frightening truth: yarn banks are dry, the promised supplies are not arriving, deliveries are delayed for months, and the only option is to buy from mills in other states at prices so inflated that the final product becomes unaffordable for ordinary families. This is not an old story being retold — it is happening right now, and it has not spared other regions of India either. Several clusters in Tamil Nadu, Karnataka, Andhra Pradesh and parts of the Northeast have reported similar shortages and price shocks in 2025.

This is a national-level supply crisis, but in Kerala the impact is especially harsh because handloom is deeply tied to livelihood, culture and seasonal demand cycles like Vishu, Onam and temple festivals.

Why this shortage exists

Let’s skip the polite explanations and go straight to the hard truths.

Mills prioritise big buyers

When spinning mills face production stress, they supply large industrial buyers first. Big brands, export units and bulk processors get priority. Small cooperatives, which place small orders and demand specific counts suitable for handloom, fall to the bottom of the list.

Production disruptions continue

Fluctuations in global demand, financial stress in spinning mills, shutdowns, power-cost issues and cotton-price instability have caused repeated disruptions through 2024–25. Whenever mills slow down, it is the handloom supply chain that chokes first.

Price volatility keeps pushing yarn out of reach

Cotton and yarn prices have been swinging unpredictably. When raw material costs rise, mills naturally favour larger clients who can pay higher rates or pre-book huge quantities. These swings crush cooperatives that depend on moderate pricing.

Export pull and policy gaps

If export orders look profitable, yarn moves out faster. In the absence of any emergency allocation mechanism for small weavers, domestic handloom clusters lose access. A policy vacuum means nobody steps in to correct this imbalance during crises.

Shift toward man-made fibres

A large portion of India’s textile investment is now flowing into man-made fibres and technical textiles. Cotton yarn — especially the types used in handloom — is no longer the priority area. This structural shift dents availability for traditional weaving sectors.

Working-capital disadvantage

Cooperatives simply do not have the financial muscle to pre-pay for bulk yarn. Mills prefer clients who can pay instantly and purchase at scale. This financial disadvantage leaves weavers stranded.

What this means for the weaver and the customer

Weavers lose work

When yarn is unavailable, the loom stays quiet. Idle looms mean idle incomes. The loss is immediate and brutal.

Products become too expensive for the common buyer

Expensive yarn becomes expensive fabric. Dhotis, sarees, veshtis, mundus, school uniforms — all become priced out of reach for middle- and lower-income households, shrinking demand further.

Younger generations walk away

When weaving becomes unstable, younger members of weaving families move to other jobs. Skills accumulated over generations vanish silently.

Cooperatives weaken

Most cooperatives operate on thin margins. Yarn scarcity pushes them toward fewer workdays, delayed production cycles and even shutdowns.

What must be done — the real, pragmatic solutions

This crisis is not unsolvable. It simply requires decisions that are timely, transparent and grounded in reality.

Guaranteed yarn allocation for handloom

A portion of essential yarn counts should be reserved exclusively for handloom clusters during shortages. This prevents complete diversion to industrial giants.

Real functioning of yarn banks

Yarn banks must stop being symbolic institutions. They need adequate stock, predictable supply cycles, and public transparency about availability and deliveries.

Build small spinning capacity near weaving clusters

Micro-spinning units — small-scale spinning tailored for handloom requirements — can reduce dependency on distant mills. This also cuts transportation costs and delays.

Pooled procurement

Cooperatives from different districts can come together to place joint orders, gaining bargaining power and locking in better pricing.

Fast-tracked working capital

Credit lines designed specifically for handloom raw-material procurement should be released quickly and without bureaucracy. Pre-payment ability is essential for securing yarn.

Protect domestic supply during crises

During acute shortages, certain yarn counts needed for handloom should be temporarily protected from export diversion until domestic demand is stabilised.

Build textile micro-hubs

Integrated regional hubs that include ginning, spinning and weaving will stabilise supply in the long term and reduce dependence on out-of-state mills.

The uncomfortable truth

This is not a crisis caused by weavers. It is the result of broken supply priorities, slow policy reactions and the absence of a safety net for an entire traditional sector. Handloom is not a luxury industry. It is a livelihood ecosystem. When yarn disappears, an entire cultural and economic heritage starts cracking.

Kerala’s weavers are not asking for miracles. They are asking for yarn — the most basic ingredient of the craft. If the state and national textile governance mechanisms cannot ensure even that, then the sector will continue to shrink no matter how many handloom days, fairs, exhibitions or publicity campaigns are organised.

The loom cannot weave air. And until raw-material supply becomes stable, predictable and fairly distributed, handloom will keep fighting for survival with one hand tied behind its back.